We’ll be able to help many countries grow high-quality vegetables, with systems that require little energy, resulting in a smaller carbon footprint.

Wouter Kuiper is CEO of KUBO. Located in the Dutch seaside village of Monster, KUBO is a pioneer in the development of greenhouse concepts.

Major players in the Dutch greenhouse horticulture sector are joining forces to showcase their knowledge and experience to a global audience. One of the goals is to help find solutions to some of the world’s biggest challenges: food production, food safety, water scarcity, and fuel.

“It’s essential that we as a sector present a unified front,” says Wouter Kuiper, a board member of the Dutch Greenhouse Delta and CEO of KUBO, a leading greenhouse builder with a sustainable approach to covered cultivation. “Up until now the Dutch greenhouse horticulture sector has been too fragmented,” he adds.

The Netherlands has extensive experience with greenhouse farming and has developed state-of-the-art technologies and products. According to Kuiper, this should be more widely known than it currently is. “So far, we have not been able to communicate a clear message abroad,” says Kuiper. “Once we can get this message across we will be able to help many countries grow high-quality vegetables. Our systems also require little energy, which means a smaller carbon footprint”.

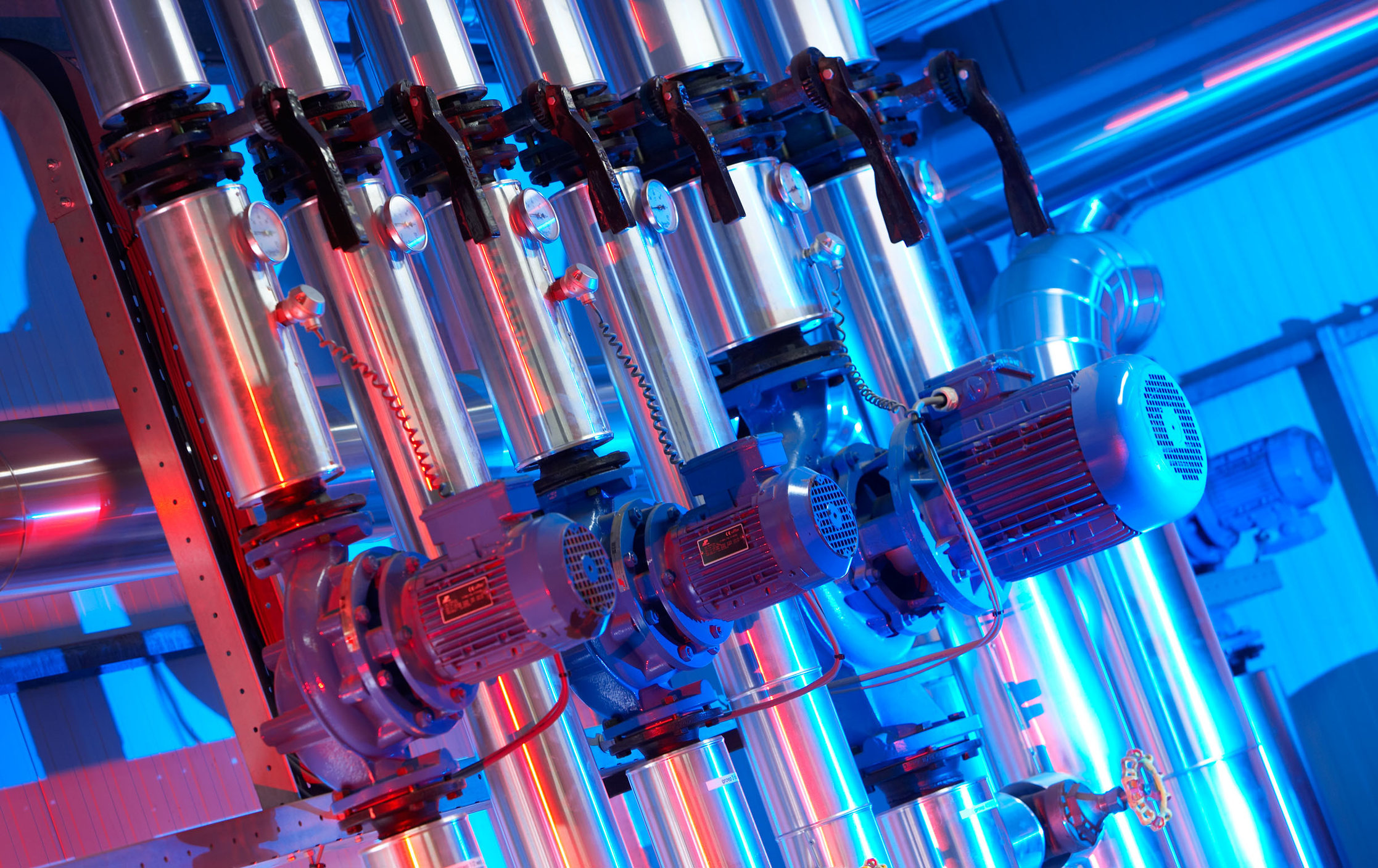

KUBO, located in the Dutch seaside village of Monster, is a pioneer in the development of greenhouse concepts. “We build the greenhouses, develop the technologies, do the growing, and provide the services,” explains Kuiper. “We invest continuously in innovation and guarantee maximum output with minimum input in terms of energy, raw materials, and water”.

The company recently completed an eighteen-hectare greenhouse project in the city of Xi’an in China, delivering the greenhouses and providing technology, support, and data analysis for tomato and bell pepper production. “The Chinese government has a long-term vision,” says Kuiper. “They want to learn how to grow plants themselves and are looking for the highest quality and the best results, not cheap solutions. Of course, other countries have their own greenhouse solutions, but the quality is not as high. If you want the best, you choose the Netherlands”.

According to Kuiper, when it comes to greenhouse horticulture, all countries face their own challenges, which can range from climate to geography all the way to legislation. “Luckily, the Dutch greenhouse horticulture sector has an answer to everything.” The demands placed by governments and consumers can also differ considerably. Some markets, for example, Austria and California, want carbon-neutral solutions, while others want food safety. “For China clean, safe food is important because in many parts of the country the soil and air are polluted”.

Pollution is not the only reason why greenhouses are often preferred in China. Climate change is making it hard to grow vegetables outdoors in many parts of the country because some areas have become too hot, too dry, or too wet. Kuiper goes on to explain that greenhouse yields are not affected by rainfall, insects, or disease vectors, regardless of their location. “Outdoor cultivation also requires on average thirty times more water than greenhouse cultivation”.

Kuiper believes this project in China is only the beginning. “They’re just testing the waters at this point. If it’s successful, which I believe it will be, they want to roll it out on a much larger scale”.

Now that the greenhouses have been built, KUBO is remotely monitoring the performance of Chinese project. Due to the many variables involved in greenhouse horticulture, it’s extremely important that greenhouse management is carried out by experienced growers. “Just one small mistake can lead to crop failure,” says Kuiper. “Growing is a craft that is often passed down through generations and one you can only learn well through practice”.

However, not all countries have enough experienced growers that are trained to using the latest and most sophisticated technology. KUBO is therefore regularly asked if there are any Dutch growers who want to work in the greenhouses abroad. “We always recommend finding a local solution,” says Kuiper. “We’re trying to make the technology easier to use. Right now, it’s rather complicated and the easier it is, the more people can use it”.

The KUBO CEO believes it’s high time that companies in the Dutch greenhouse sector start collaborating. He hopes that a large number of horticulture companies, relevant suppliers, and growers from the Netherlands will join the Dutch Greenhouse Delta (DGD).

“The more the better. We need to do this together: firstly, for the people in all those countries that need more and better food; secondly, for the greenhouse industry in the Netherlands; and thirdly, for our companies”.

He thinks it’s an important step that AVAG (the association of the Dutch greenhouse installation and technology sector) and LTO Glaskracht (the entrepreneurial greenhouse network, of which many growers are members) support DGD. “This emphasizes that it’s an industry-wide initiative, not just an organization for greenhouse builders”.

The foundation offers companies two types of membership: full membership, for €25,000 per year, which promises to provide transparency and insight into all incoming projects, and a so-called sponsor membership, which costs €5,000 per year, and is especially designed for companies interested in supporting the DGD while staying up-to-date on the organization’s developments.

Kuiper says the horticulture sector learned from mistakes made in the past and he is convinced that the joint effort will prove successful this time. “There is more willingness to collaborate now. The set-up is transparent and non-competitive for the members. Everyone in the greenhouse sector is talking about joining forces, so the timing is perfect. The fact that it’s taken this long has been a thorn in the industry’s side for years now”.

Europa 1

2672 ZX Naaldwijk

The Netherlands

All rights reserved 2025